Hydraulic tube and pipe fittings are most commonly used with three different types of port threads:

1) SAE Straight Thread "O" Ring 2) ISO Metric Thread "O" Ring 3) National Pipe Thread

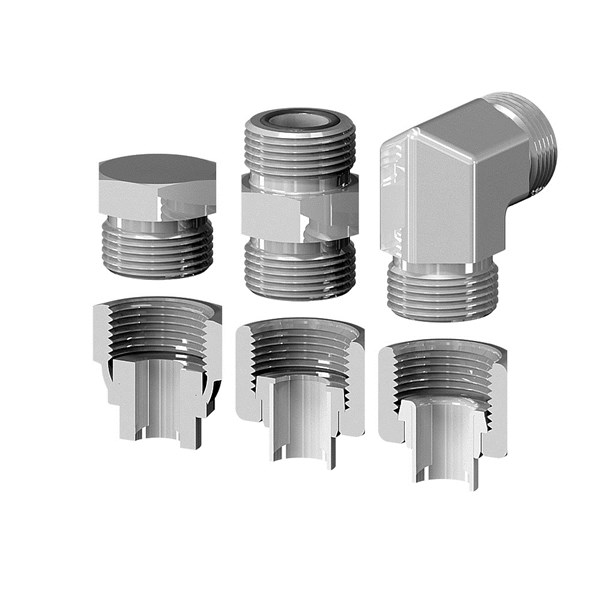

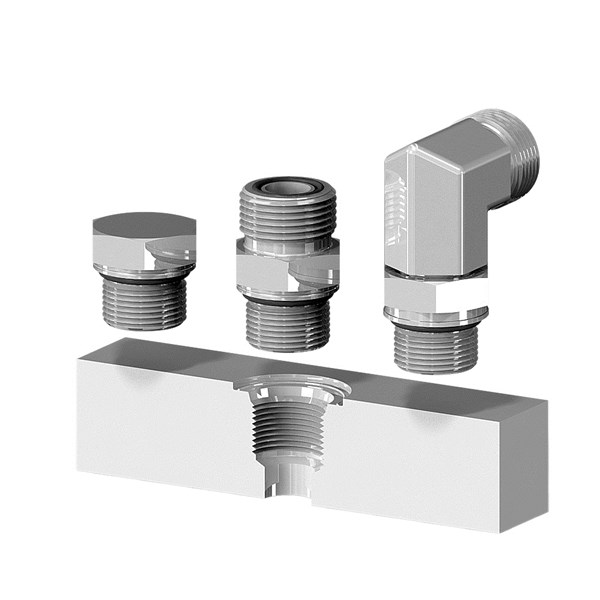

SAE STRAIGHT THREAD "O" RING PORTS

SAE straight threads can be machined for either adjustable or nonadjustable hydraulic fittings. Carefully machined internal and external UN/UNF straight threads provide the holding power for hydraulic fittings when installed in high pressure hydraulic systems.

SAE straight threads sealing power comes from the use of a high quality 90-durometer Buna-N "O" Ring as specified by SAE-J514. During assembly, the straight threads provide adjustability on shape fittings where maneuverability and alignment are necessary for tube line routing.

After the hydraulic fittings with the SAE straight thread have been properly installed, the hydraulic "O" Ring provides a high pressure seal by becoming seated between the angular groove in the female port and the male end of the hydraulic fittings.

ASSEMBLY INSTRUCTIONS

- Inspect the hydraulic fitting and mating port to ensure that there is no foreign matter present or nicks in the "O" Ring to cause a leak.

- Lubricate the "O" Ring with a light coating of oil or hydraulic fluid.

- On the fittings adjustable thread, back the locknut off as far as possible and screw the fitting into the port until the flat back-up washer makes contact with the face of the port.

- Align the adjustable fitting with the end of the tube assembly by unscrewing the fitting to the proper direction. (Do not unscrew the fitting more than one full turn.)

- Using a wrench to hold the fitting in the desired position, tighten the locknut to the proper torque value as shown in the torque chart for adjustable SAE threads.

- Visually inspect the fitting assembly to confirm that the "O" Ring has seated properly in the female ports angular seating groove and the back-up washer is seated flat against the face of the port. Inspect threads before assembly to be assured that the male thread and female port are free of burrs and other foreign matter. Lubricate the hydraulic "O" Ring before installing the fitting to prevent the "O" Ring from possible damage during installation. Hydraulic fittings machined from forgings may have higher assembly torque values than are shown in the chart below. (See drawing below for example of proper installation.)

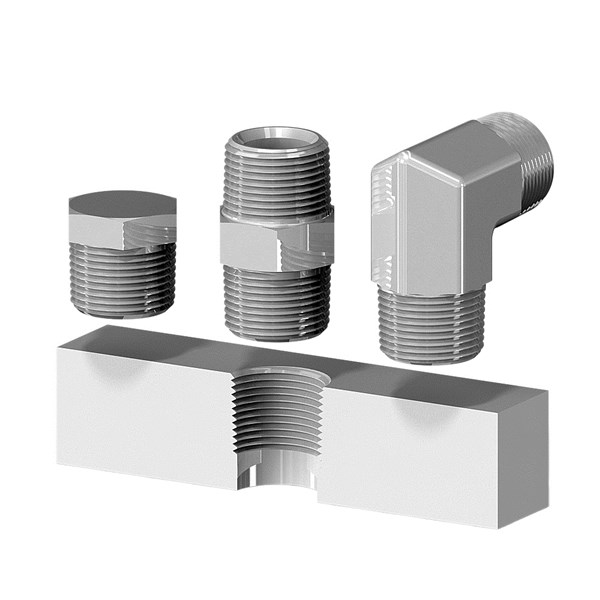

DRYSEAL PIPE THREADS

NPTF threads are formed to have a 3/4" taper with tightly machined tolerances to provide contact at the crest and root of the thread as well as the flank. The metal to metal seal of the thread crest, root, and flank, together provide a complete seal to help prevent the possibility of spiral leakage. NPTF threads also provide the holding power for the

connection while in high pressure service, which limits the reliability of the seal which the threads are making

with the female port.

For high pressure applications where constant vibration is running through the hydraulic systems, hydraulic fittings with SAE straight threads which connect to female or male ports are recommended.

ASSEMBLY INSTRUCTIONS

- 1. Visually inspect the fitting and the mating port and remove any burrs or foreign matter whichmay be present.

- Apply thread sealant if needed to the male threads. Do not apply thread sealant to the beginning 1/3rd of the male threads so as to keep the hydraulic system free from being contaminated by sealant which enters the system from the fitting connection.

- Install the fitting to the finger-tight position. Using a wrench turn the fitting approximately 2 - 2 1/2 turns past the finger-tight position. (See drawing below for example of proper installation.)

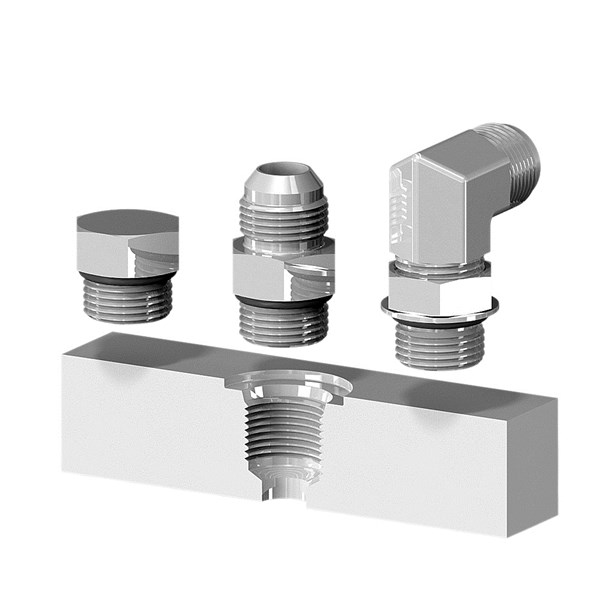

(Face Seal Assembly Size-2.eps)

(Pipe thread port Assembly.eps)

(Straight thread metric port Assembly.eps)

(Straight thread port Assembly.eps)