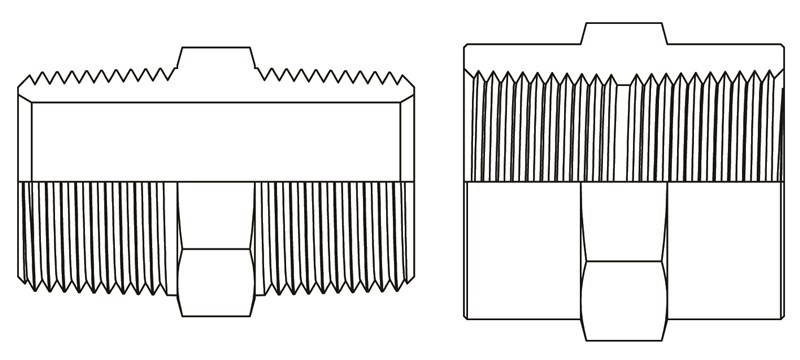

Straight pipe fittings are machined from cold drawn bar stock. Shape fittings (elbows, tees, and crosses) are made from forgings. 3000 Series pipe fittings are machined with NPTF threads for greater holding power and resistance to leakage.

For use in lubrication, instrumentation, and most high pressure hydraulic systems.

Working pressures up to 5000 PSI – Working Pressure will vary depending on Tube & Fitting Size. (For applications using extreme pressures at 5000 PSI or above, contact World Wide Fittings.)

Steel – 12L14, 1045

Stainless Steel – Type 316

Clear Zinc Trivalent

Passivated

3000 Series pipe fittings are available in sizes 1/8” through 2” (Contact World Wide Fittings for availability of specific shapes and sizes.)

3000 Series fittings meet SAE J514 specifications.

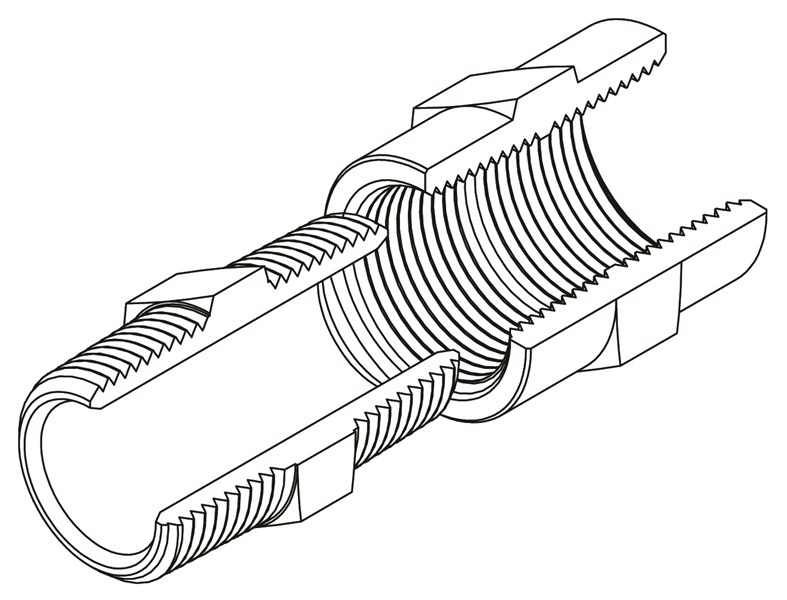

3000 Series Assembly

Dryseal Threads:

- Inspect the male and female threads for cleanliness.

- Lightly lubricate the male and female threads.

- Using a wrench turn the fitting approximately 2 – 2 1/2 turns past the finger-tight position. (Thread sealant may be applied for added protection against leakage.)

SAE “O” Ring Threads:

- Inspect the male and female SAE straight threads

- for cleanliness.

- Lubricate the hydraulic “O” Ring before installing the fitting to prevent the “O” Ring from possible damage during installation. Install the fitting to the finger-tight position.

- Using a wrench tighten the fitting to the proper torque value.